The global plastics processing industry continues to evolve rapidly, and with it, the demand for high-performance equipment is stronger than ever. Inter has machinas, the Plastic Pelleting Machine munus centrale agit in processibus redivivis et componendis. While many components contribute to its overall efficiency, experts emphasize that the screw design is one of the most critical factors determining output quality, energy consumption, and production stability.

Momentum stupra Design in Pelleting Operations

1. Ensures Congruentes Material Conveying

Cochlea of a Plastic Pelleting Machine auctor est ut materias rudis per mansiones pascendas, liquefaciendas, permixtionem et pressorium transportandum. A well-engineered screw ensures smooth and consistent conveying, preventing issues such as material backflow, blockages, or irregular pellet size.

2. Enhances Plastic Liquefactio Efficiency

Efficacia liquatio directe afficit globulo qualitatem. Ratio compressionis cochleae, profunditas fugae, geometria canalis determinant quam cito et aequaliter liquefaciat plastica. Cochleae bene dispositae adiuvat ad distributionem uniformem caloris et temperationis stabilitatem moderandam, et fidem et efficientiam augendo.

3. Improves Mixtionem et Homogenization

Materiae variae - ut resina virgo , carnium cyclum , et additiva - mixtionem requirunt ut globulos summus qualitas edant . Cochleae mixturae zonae, notae tondendi, ratio longitudinis diametri (L/D) partes clavis ludunt in liquefactione homogenea consequendo. Hoc evenit in globulos cum proprietatibus mechanicis melioribus et coloratis consistentibus.

4. Auget Output et reduces Energy consummatio

Geometria et schematisma cochleae determinant quomodo energia efficienter convertatur in processus mechanicos et scelerisque. Optimized screw design reduces torque load and improves throughput, allowing manufacturers to produce more pellets with less energy—an essential advantage in today’s competitive and environmentally conscious market.

5. adaptat ad diversas materias et Applications

Processus plasticus modernus amplis materiis implicat, inclusa PE, PP, ABS, PET et alta magisterbatch impleta. Lorem cochlea consilium dat Plastic Pelleting Machine varias materias procedere sine qualitate detrimentum, faciens apparatum mobiliorem et cost-efficacem.

Key Screw Design features quod differentiam faciunt

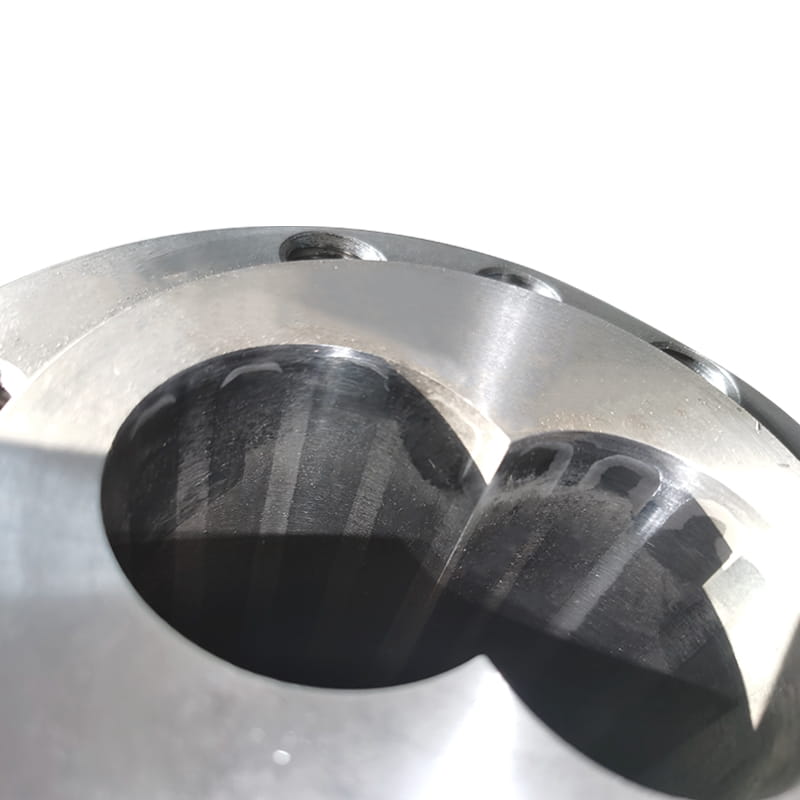

1. fuga Geometria

Figura et angulus volatus cochleae afficiunt fluxum plasticum et pressionis buildup. Provecta geometria minimizat accentus tondendas cum efficacia maxima.

2. Ratio compressionem

A suitable compression ratio ensures proper melting and venting, preventing defects such as unmelted particles or gas bubbles in the final pellets.

3. Mixing Sections

Statica et dynamica permixtio elementa augent uniformitatem liquefaciunt, praesertim colori magisterbatch et materia plastica REDIVIVUS.

4. Longitudo-ad-diameter (L/D) Ratio

A longer L/D ratio generally improves melting and mixing performance but must be chosen according to material characteristics and production requirements.

conclusio

In hodiernis plasticis crescentibus redivivus et componens industriam, consilium cochleae in a Plastic Pelleting Machine is more than a technical detail—it is a core factor that determines production efficiency, energy consumption, output quality, and long-term operational stability. Manufacturers increasingly turn to optimized or customized screw configurations to stay competitive and meet the rising standards of modern plastic production.

As the industry continues to prioritize sustainability and high-performance manufacturing, the importance of advanced screw design will only continue to grow.