In ingens landscape de plastics vestibulum et redivivus, in Plastic Pelleting Machina stat quod essential fragmen industriae apparatu. Also frequently referred to as a pelletizer, granulator, or compounding line (when integrated with mixers and extruders), its core function is to transform plastic materials – whether virgin resin, recycled flakes, or compounded mixtures – into small, uniform, free-flowing pellets or granules, often called "nurdles."

Core munus et processus:

A Plastic Pelleting Machina Fundamentaliter accipit plastic in fusum vel mollium et convertit in consistent pellem formam. Et typical processus involves:

-

Pascens: Plastic Feedstock (flages, regrind, componi conflandum) introducitur in machina.

-

Extrusionem / liquescens (saepe praecedens vel integrated): Dum aliquid pelletizers operis directe cum fusilia polymer ex flumine extruder, alii potest habere integrated extrusionem capabilities ad conflandum solidum feed.

-

Pellet formation (mori faciem cutting aut litus pelletizing):

-

Die facies secare: More plastic coactus per mori laminam quibus numerosis parva foramina. Sicut firma emergere, rotating lamminas interficiam eos in pellets directe ad mori faciem.

-

Strand Pelletizing: Flilat plastic extruditur per mori formare multiple continuas. His firma refrigerantur plerumque aqua balneum et pavit in separatum unitas ubi rotating laminis dolor in uniformis globulos.

-

-

Refrigerant: Mox secans, pellets sunt cursim refrigerari (per aere vel aqua) ad solidatur eorum figura et ne clumping.

-

Siccatio (si aqua refrigeratum) Pellets refrigeratum in aqua requirere efficiens siccatio systems (centrifuga dryers, fluidized lectum dryers, etc) ut aufero humorem ante repono et packaging.

-

Collection: Finitoque pellets importatur repono Silos aut packaging unitates.

Key components:

A vexillum Plastic Pelleting Machina System typically integrata plures discrimine components:

-

Pascere Hopper / PASTOR: Ensures consistent materia initus.

-

Extruder (integrated et flumine): Liquefiat et homogenizes ad plastic. Single vel geminae screw consilia communia.

-

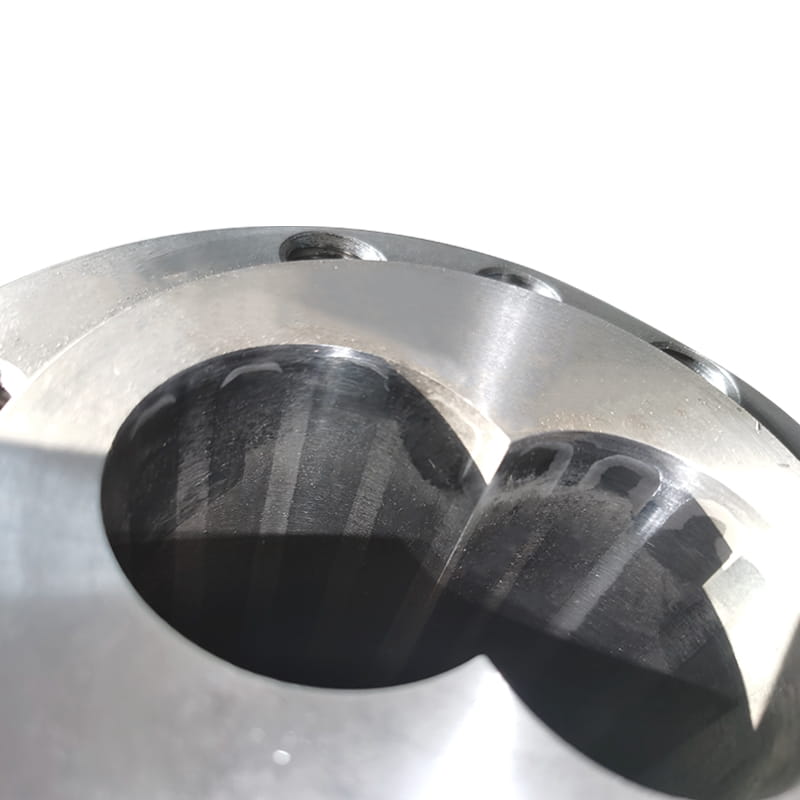

Die Plate: Metaretur et praecise obduratum foramina plastic figura firma in firma.

-

Secant Cubiculum / Unit: Domibus rotating cutter centrum et laminis, quod tondendas plastic firma in Pellet.

-

Cutting laminis: Strame laminis mounted in cutter hub; Celeritas et acumen sunt crucial pro pelliceo qualitas.

-

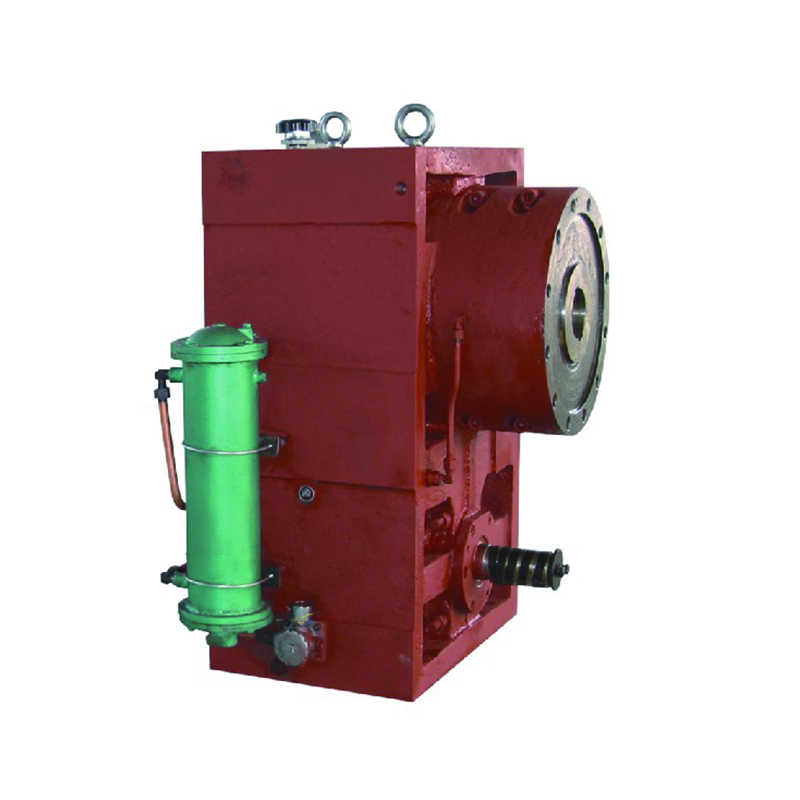

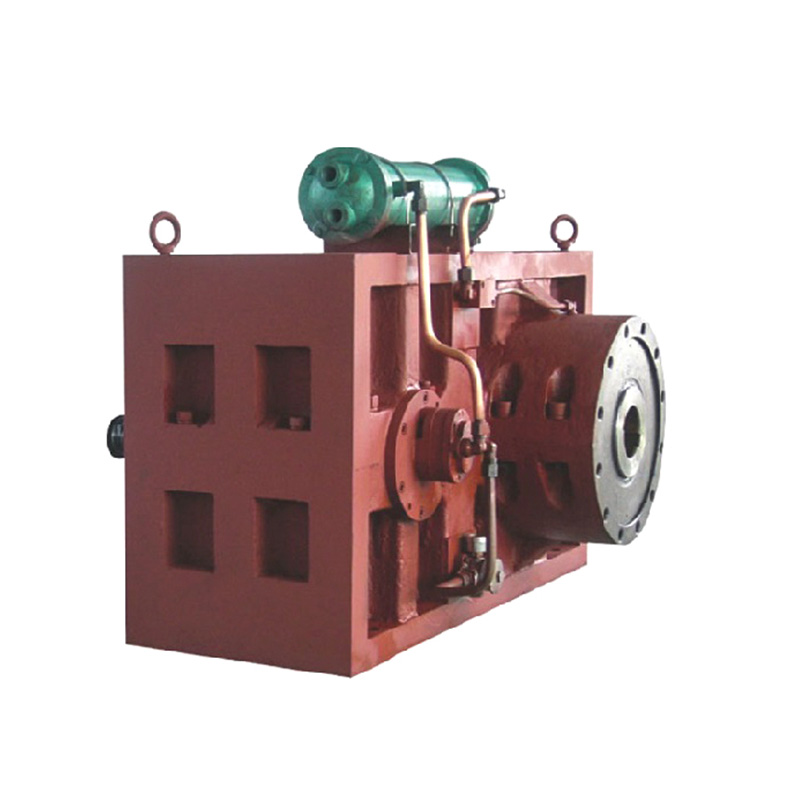

Coegi ratio: Potestates et Cutter Hub conversionem.

-

Refrigerant ratio: Aeris cultris aqua imbre aut aqua balneum solidifying globulos.

-

Siccatio system (si dici): Removet RELICTUM aqua.

-

Imperium Panel: Manages motricium celeritates, temperaturis et alia operational parametri.

Materials processionaliter:

Plastic Pelleting machinis Palpate late ordinata thermoplastic polymers, comprehendo:

-

Polyethylene (PE - LDPE, LLDPE, HDPE)

-

Polypropylene (Pp)

-

Polystyrene (Psalm - GPPs, Coxis)

-

Polyvinyl chloride (PVC)

-

Polyethylene terephthalate (pet)

-

Acryonitrile Butadiene Styrene (Abs)

-

Engineering Plastics (E.G .: Nylon, PC, Pom) et variis recycled aut compositum mixtionis.

Et commoda Pelletizing:

Converting plastic in pellets per a Plastic Pelleting Machina Serves aliquot vitalis proposita in Polymer Industry:

-

Standardization: Figura magnitudine partle creates uniformis, essentialis pro consistent pascens et dispensando in downstream apparatu sicut iniectio folders vel extruditoribus.

-

Improved Tractantem & onerariam: Pellets fluxus libere, dissimilis irregulares flages vel pulveres, faciens ea significantly facilius ad onerariis (in mole vel sacculos), copia, et meter automatice in dispensando machinis. Densitas augetur, optimizing shipping volumine.

-

Enhanced materiam proprietatibus (quia recycled): Nam REDIVIVUS plastics, Pelletizing homogenizes ad conflandum, improving qualis et processability comparari directe per Flake.

-

Densificatio: Reduces in volumine de molesta plastic flagellis vel regrind, ducens ad magis agentibus repono et logistics.

-

Qualitas imperium: Providet imperium forma factor quod facilitates qualis checks (contaminationem, color crassitudinem).

-

Feedstock ad vestibulum: Pelletized Virgo vel Recycled Plastic est primaria feedstock pro virtualiter omnes plastic product vestibulum processus.

Applications:

Plastic Pelleting machinis sunt necessaria in:

-

Plastics Redivivus Facilities: Converting Post-Consumer aut Post-Industrial plastic perditio (utres, films, vasis) in uniformis globulos ad reuse.

-

Componentes plantis: Producendo consuetudinem plastic formulae a miscere basi resinam cum additives (Colorants, fillers, supplementum, modifiers) et pelletizing finalis compositis.

-

Virgin resinae productio: Final scaena in resin vestibulum plantarum ad sarcina productum for sale.

-

Reprocessing Operations: Converting in-Domus productio Scrap (Strues, Off-Spec partes) Back in utilis pellem Pellet.

In Plastic Pelleting Machina multo magis quam magnitudine reductionem instrumentum. Est fundamentalis dispensando unitas, quod transforms plastic materiae - Virgin aut Recivycled - in altus muneris, mensuris, et efficientem factor. Per producendo consistent pellets, horum machinis enable reliable fluxus materia per universa vestibulum et redivivus vincula, underpinning efficientiam, qualitas et oeconomica viability modern plastica industria. Illorum munus est discrimine in claudendo ad loop ad plastic susinability et ensuring optimal perficientur in ultima uber vestibulum.