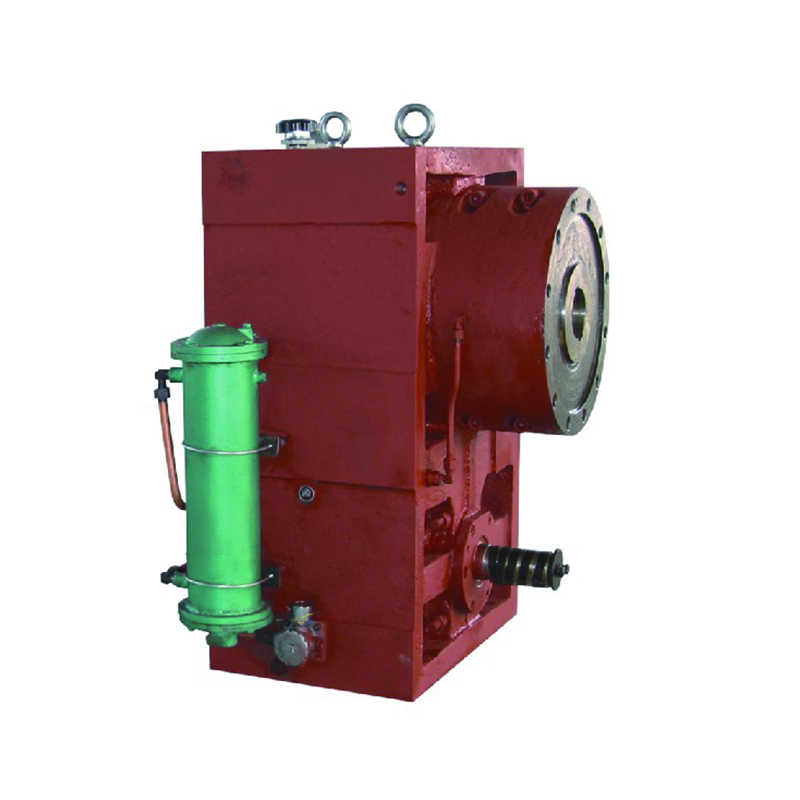

Intra postulat realm of extrusionem - plastics, cibum, componendo, et supra - et stupra et dolium conventus stat sicut cor processus. Engineers constanter quaerite consilia quae optimize liquescens, miscentes, pressura generationem et stabilitatem. Inter key choices falsa fundamentalis geometria: conicis vel parallel. Dum parallelae screw dolia dominari plures applications, conicis consilia offerre distincta commoda crucial propria, saepe provocantes, productio requisita.

Tractatus Primo: Defining Cogitationes

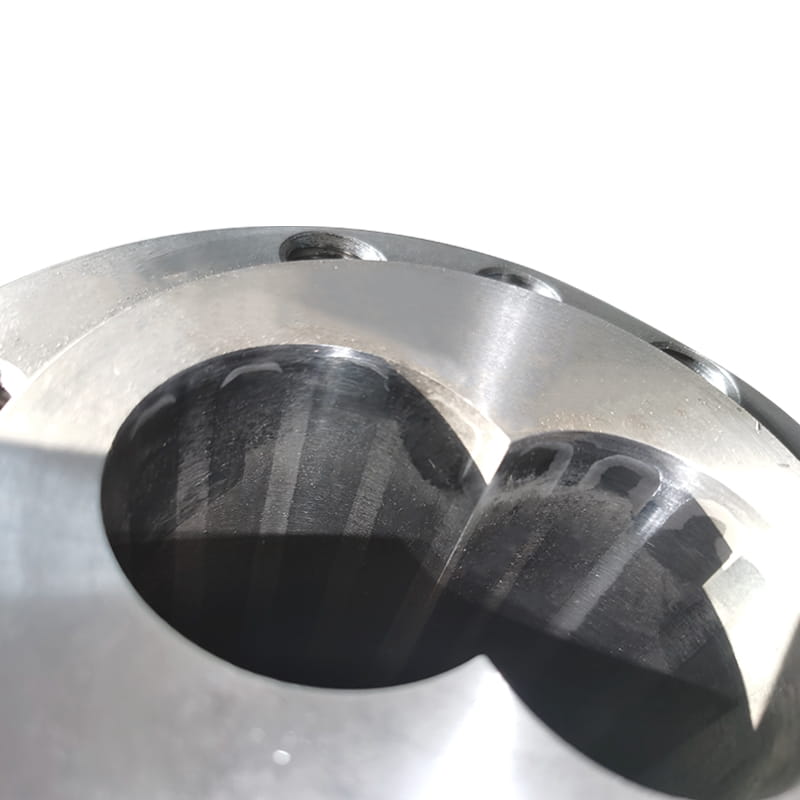

- Parallel stupra cadoS: Feature constans exterius dolio diameter et cochlea cum constans radix diameter (vel minor variationes per egressus fuga). Cannem profundum typically diminuitur in stupra longitudinem generare compressionem.

- Conical screw dolium s: Propria perna quorum internum diameter tapers Interna a feed Zonam ad metering zone. Correspabiliter, cochlea features a conica radix quod crescit diametri per longitudinem naturaliter partum progressionem alveo profundum.

Clavem commoda conica screw Designs:

-

& Enhanced liquescens homogenization:

- Gradual compressio: Et inhaerens taper gignit a significantly leviore et magis continua compressio profile comparari ad saepius abrupta compressionem gradibus possibile in parallela consilia. Hoc gradatim reductionem in channel volumine subditorum materia est iam, magis imperium tondendas et compressionem copias.

- Shear distributio: Hoc temperatus environment promovet magis efficiens liquescens de polymer pellets vel pulveres per channel crucem-sectionem, ducens ad meliorem homogenization de tabescere et dispersionem additives vel fillers. Hoc praecipue utile est calor, sensitivo materiae vel formulationes requiring lenis sed penitus miscentes.

-

Improved pressura buildup & stabilitatem:

- Continua pressura gradiente: Conical geometria naturaliter generat ausculos, magis linearibus pressura buildup per stupra axem. Hoc minimizes pressura spicis et fluctuations saepe periti subito compressionem zonis in paralleloch.

- Stabilis metering: Et firmum pressura profile translates directe in magis consistent ad conflandum fluxus intrantes mori caput. This results in superior dimensional stability and consistency of the extruded product (e.g., pipe wall thickness, sheet gauge, profile dimensions), reduced scrap rates, and improved process control, especially critical for high-precision extrusion tasks.

-

Reducitur Shear Accentus & scelerisque Degradation (potentiale):

- Inferius apicem tondendas: Dum conico Cochleas generate significant tondendas, distribution De Shear viribus est saepe latius et minus intensus in aliquo uno comparari ad excelsum localized tondendas quod potest fieri in restrictiva zonas (sicut compressa fuga vel miscentes elementa) in parallelochs.

- Materia mansuetudo: Hoc proprium facit conica consilia maxime bene apta dispensando tondebis-sensitivo materiae (E.G .: PVC, quidam Engineering Polymers, Bio-Polymers, Fiber Degradations vel fibra fractio est. In gradual pressio adjuvat administrare conflandum temperatus ortum magis uniformiter.

-

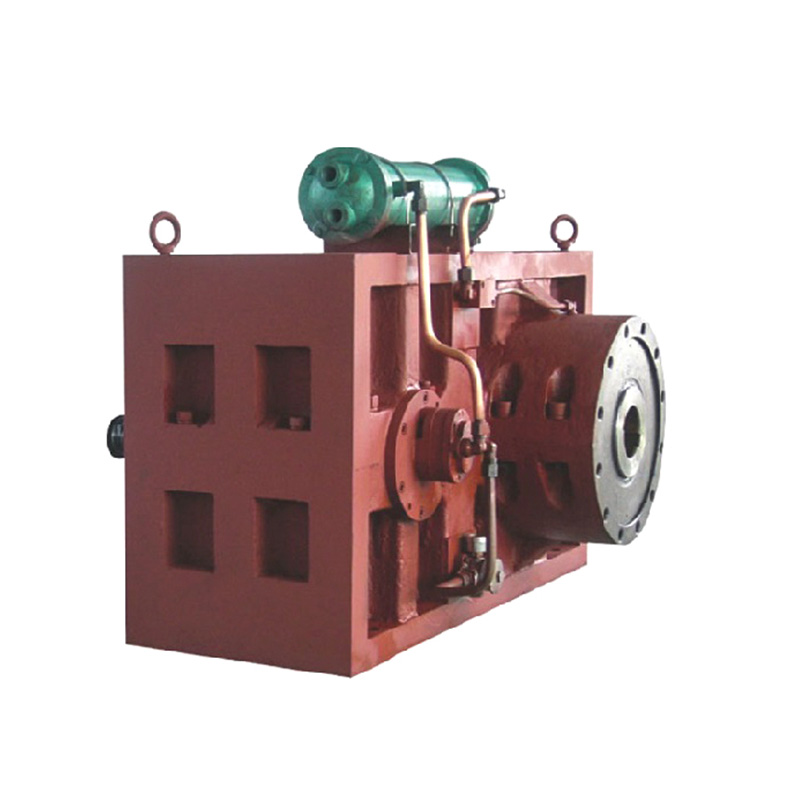

Enhanced pertractatio de provocantes materiae:

- Pulveres & FRUBILIS FORDINK: In geometriam potest offerre commoda in pascens et onerare humilis-mole-density pulveres vel friable materiae, ut a taper iuvat leniter consolidare in feed mane in processus sine nimia backflow.

- Recycling & contaminated feed: Et robust directionem et liquescens characteres potest aliquando providere magis tolerantia ad regrind aut feedstocks cum minor contamination variationes.

-

Potential enim superiore output ad minus RPM:

- Efficientis solidorum, Initial alveo abyssi proxima ad feed faucium potest augendae solidos solidos capacitatem comparari ad vadum pascens parallelum cochlea.

- Optimized Energy Translatio: In efficientiam et liquefacti et pressura generationem in Conical Design potest aliquando patitur operators ad consequi scopum outputs dum currit in cochlea ad paulo inferioris parallel setup. Haec translates reducitur specifica industria consummatio (industria per unit output) et potentia minus gerunt in tempore.

Maximus considerations:

Conical screw cados non universaliter superior. Plus pronuntiari propria missionibus

- Processing petit: Critica ad tondendas-sensitivo materiae, formulations requiring eximia excelsam homogeneity, seu applications postulantes maxime firmum pressura et output (E.G., summus praecisione profiles, Medical Tubing, optical film).

- Economic commercia, offs: Conical consilia saepe magis universa et pretiosa ad fabricare et reponere quam paralleloch. Arma calefactio / refrigerationem potest etiam esse leviter magis universa debitum ad taper.

- Vestigia: Taper necessitates longioris dolium conventus comparari parallela stupra assequendum similes compressione potentia impacting machina magnitudine.

Et choice inter conicis et parallelae cochlea dolia cardine in propria materia, productum requisita, et processus proposita. Parallel Cochleas offerre versatility et sumptus-efficaciam pro ingens range of applications. Tamen, cum postulat includit superior tabescet qualis, eximia pressura stabilitatem, reducitur tondendas accentus ad sensitivo formulationibus, aut pertractatio provocantes Feedstocks, inhaerens commoda de conica screw fascinare fiet cogens. Et gradual compressionem profile delivers efficient liquefactis, firmum fluunt, et auctus processus imperium, faciens ea probatur solutionem postulat extrusionem, ubi perficientur consistency et materiam integritas sunt non-MERCABILIS. Operators diligenter aestimare processus requisita adversus core commoda determinare optimal geometria.