In contextu autem continua studio viridis vestibulum et sumptus optimization in plastic processus industria, industria consummatio imperium ex extruditoribus ut core industria-intensive apparatu est magis discrimine. Industria experts designandum quod de fine temperatio de clavis parametri Conical screw dolium probatum est esse efficax breakthrough in reducendo unitas industria consummatio. In his focuses in tres core Optimization Insidijs:

I. Screw geometriam: De Angularis de industria-agentibus consilium

Maccatio taper matching: accuratius aequare in taper cum materia proprietatibus (ut PVC scelerisque sensitivity) ad optimize solidum et liquescens efficientiam. Nimis magna a taper et faciam super cultro in liquefacta zona, et quoque parva a taper erit consequuntur in insufficiens compressione - tum auget ineffective industria consummatio.

Prisamice compression Ratio: Mos Ratio compressionem Ratio (plerumque 2.5-4.0) secundum mutationem in rudis materia density (pulveris ad conflandum) ut a lenis et efficientem tondentes vel pauperes exhauriunt.

Thread structuram et plumbum: nam altus repleti vel tondere-sensitivo materiae, usum optimized miscentes elementa (ut egling angustos angulus, width) et ducere mutationes potest significantly redigendum virtutis consummatio cum ensuring potest significantly.

II. Processus Parameter Coordination: et clavis ad operating efficientiam

Temperatus curve Optimization: Vitare Simple linearibus incrementa paro values ad invicem temperatus zone. Set precise temperatus potestate secundum materiam liquescit curva, praesertim ne superheated conflandum ab intrantes metos sectione, quae potest reducere calefactio industria consummatio et refrigerationem onus.

Celeritas et torque statera: High Volo ≠ excelsum output. Sub praemissa ex extrusionem stabilitatem, invenies optimum statera inter stupra celeritate, torque et output. Reductionem in motricium efficientiam fecit a cultro est occultatum industria consummatio captionem.

Back pressura denique-tuning: appropriately reducendo ad tergum pressura de metering sectione (sub praemissa exsequiis plasticization qualis) potest efficaciter reducere in stupra onus, et coegi motricium current potest reduci per V% -15%.

III. Gerunt Cras et praeventionis: protegens Long-terminus industria efficientiam

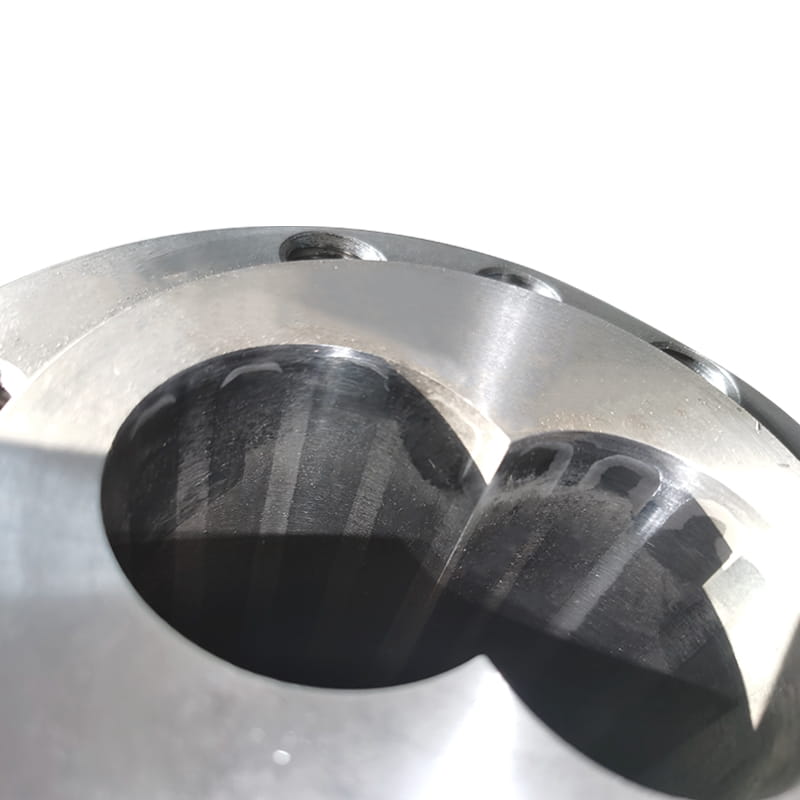

Gap Management: regularly et verius deprehendere gap inter stupra et dolium. Cum gap excedit vexillum, ad tabeant reflow rate crescit (mensuras notitia saepe excedit XV%), quod significat quod industria consummatio auget significantly ad idem output. Opportune reparatione vel replacement est oeconomica arbitrium.

Surface strengthening technology: For specific abrasive materials (such as glass fiber reinforced materials), nitriding or bimetallic treatment processes are used to improve the surface hardness and wear resistance of the screw/barrel and maintain long-term operating gap stability.